📄🎥 Introduction to Purchasing & Receiving

This article is an Introduction to Purchasing & Receiving discussing topics such as Workflows and basic Calculation Methods.

Introduction

- This article covers the basic principles of the three main methods of Stock Ordering/Receiving

- Bepoz also supports receiving electronic invoices, however, this feature is only available in Australia at this point in time and only for Suppliers that support this mode

- The main methods of receiving stock into BackOffice within Bepoz for Stock Control purposes are Manual Receipt, Manual Purchase Order and Automatic Purchase Order

- The orders can be based on different factors such as:

- Min Max - if below the Min order to the Max.

- Min - if below the Min order to the Min.

- Max - if below the Max order to the Max

- Sales - order a specific period's sales quantities e.g. previous week's sales or current month's

Prerequisites

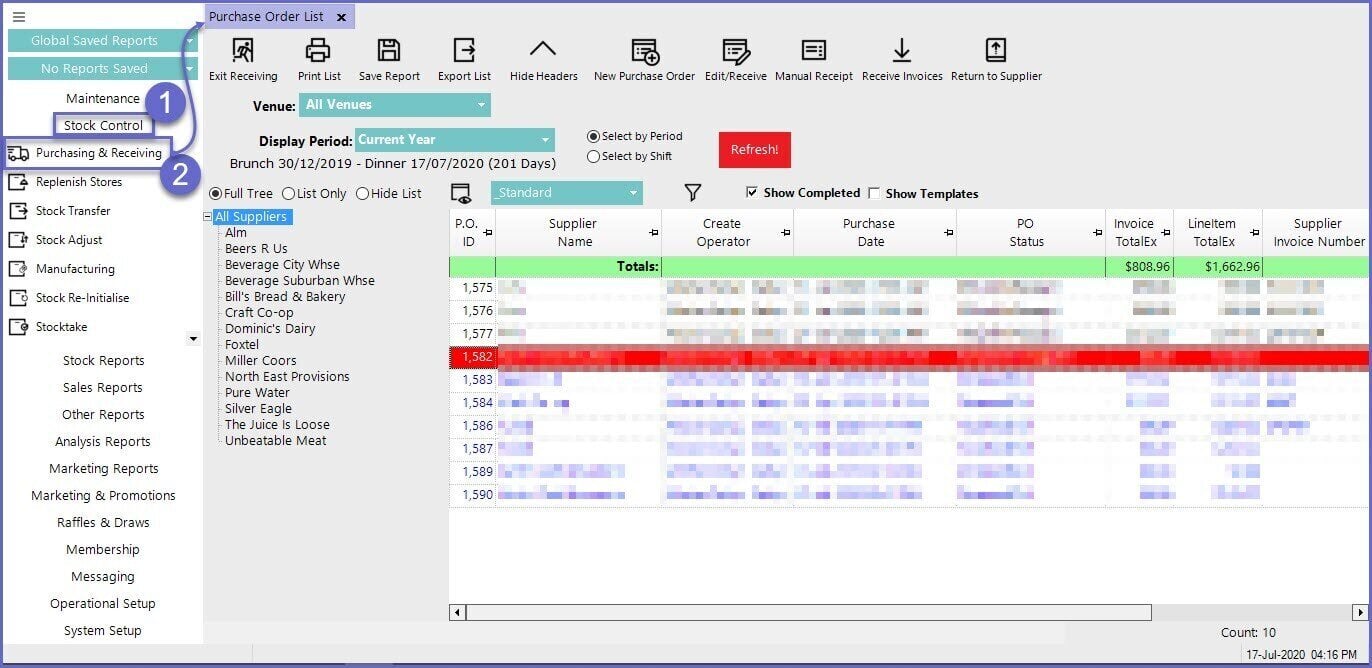

- To access and edit Purchase Order Settings, the applicable Operator Privileges will need to be enabled:

- All "Purchasing and Receiving" Flags

- Operator Maintenance 'Stock Control' Tab

Getting Started

- To create a New Purchase Order or Receive an Order, follow these steps after logging into BackOffice

- Navigate to the Stock Control from the Side Menu

- Click on the Purchasing & Receiving option which will open a window titles Purchase Order List

General Options

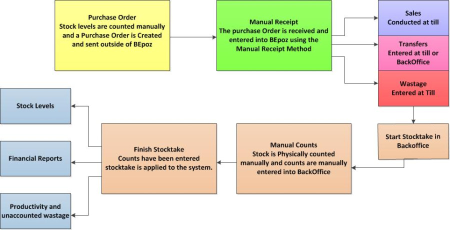

Workflows Manual Receipt Stock Flow

- The Manual Receipt method is the most rudimentary

- When a purchase order is placed with a supplier nothing is entered into BackOffice

- The stock and cost levels are updated by manually entering each receipt

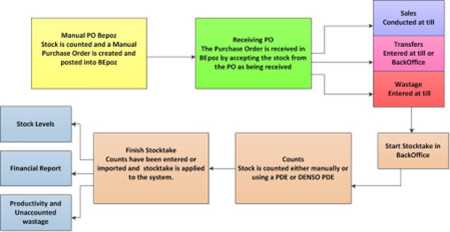

- The Manual Purchase Order enables operators to have more control over the ordering processes

- It entails entering the purchase orders into BackOffice and sending them to the supplier

- The stock is accepted by checking it against the existing Purchase Order

- This eliminates the possibility of double ordering and simplifies and speeds up the receiving process

- Automatic Purchase Orders are the quickest way of organising stock

- It involves setting the stock par levels (Minimum and Maximum) and ordering parameters for each product within BackOffice

- The Purchase Orders are then automatically generated in BackOffice

- The quantities in the auto P/O can be easily changed before being sent

Video Walkthrough